Korean Air Supply Chain Challenges are at the forefront of industry discussions as the airline grapples with significant operational hurdles. Under the leadership of CEO Walter Cho, the company is navigating complex aviation supply chain issues, aggravated by the Trump tariff impact on imported parts and materials. The recent merger with Asiana Airlines has added layers of complexity to these challenges, as Korean Air aims for growth amidst shortages of planes and engines. As competition intensifies in the airline industry, strategic solutions are crucial to overcoming these hurdles to secure a competitive edge. The implications of these supply chain challenges extend beyond immediate operational concerns, shaping the future trajectory of the airline.

The ongoing hurdles in the operational framework of Korean Air have become a focal point for discussions surrounding the broader airline industry challenges. As CEO Walter Cho addresses the pressing issues related to supply chain logistics, the company faces heightened scrutiny in light of the recent merger with Asiana Airlines. The repercussions of global trade tariffs, particularly under the previous administration, have created significant barriers to acquiring essential assets like aircraft and engines. With the stakes at an all-time high, the aviation sector is witnessing an urgent need for innovative approaches to supply chain management. Navigating these complexities is not just about survival; it’s about thriving in a highly competitive market.

Korean Air Supply Chain Challenges

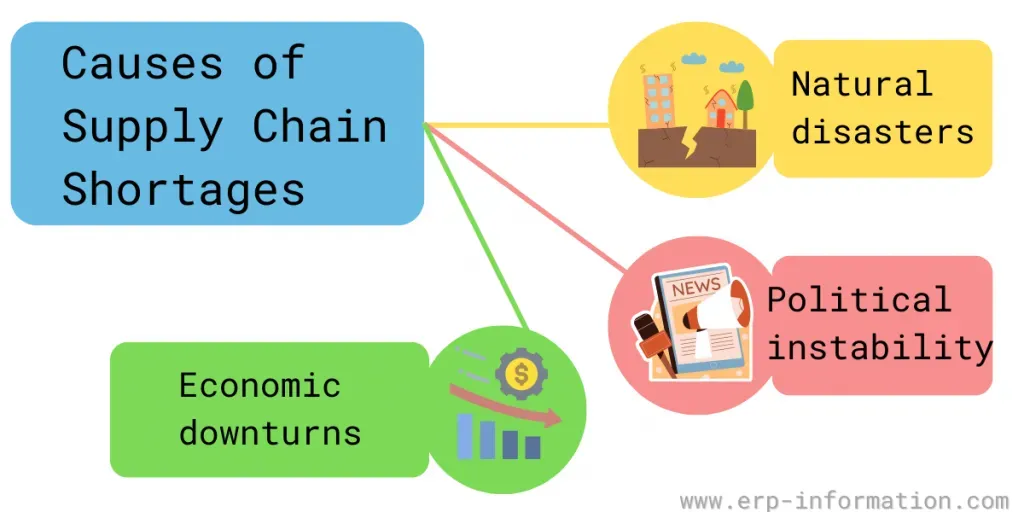

Korean Air is currently grappling with significant supply chain challenges that are affecting its operational capabilities. The CEO and Chairman, Walter Cho, has brought attention to how shortages in essential components, such as aircraft and engines, impede the airline’s ability to meet growing demand. As the aviation industry rebounds from the global downturn caused by the pandemic, these shortages become increasingly critical, highlighting the need for efficient supply chain management. In addition, navigating through complex tariff issues imposed during Trump’s administration further exacerbates the difficulty of procurement, making it imperative for Korean Air to devise effective strategies to address these challenges.

Moreover, the impact of ongoing supply chain issues can extend beyond just operational hiccups, influencing customer satisfaction and brand reputation. As Korean Air focuses on its merger with Asiana Airlines, it becomes even more crucial to synchronize their supply chains to create a robust operational framework. The joint entity must prioritize overcoming these aviation supply chain issues to ensure a seamless transition and robust future growth. The efficient acquisition of aircraft and engines will not only help meet the immediate needs but also align with long-term strategic goals to enhance competitiveness in the airline industry.

The Impact of the Korean Air Merger with Asiana

The merger between Korean Air and Asiana Airlines is set to transform the landscape of air transportation in South Korea. This strategic alignment aims to consolidate resources and expand market reach, but it also introduces a slew of challenges, particularly regarding integration processes. For Walter Cho, the CEO of Korean Air, successfully navigating through these merger-related hurdles is crucial for establishing a unified front in a highly competitive sector. The merger is expected to yield substantial synergies; however, the supply chain shortages faced by Korean Air have raised concerns about the timing and execution of this consolidation.

Furthermore, the merger will likely impact the operational dynamics between the two airlines, necessitating harmonization of supply chain workflows. To realize the full potential of this merger, both companies will have to confront existing aviation supply chain issues with innovative solutions. This includes negotiating better terms with suppliers and exploring new sourcing avenues to ensure that the airborne fleet can meet customer expectations without delay. The success of this merger hinges on effectively overcoming these logistical challenges to position the combined airline for future growth.

Navigating Aviation Supply Chain Issues

Aviation supply chain issues have been a persistent concern for airlines globally, and Korean Air is no exception. The challenges stem from a mix of global disruptions, including trade tariffs and logistical bottlenecks. Walter Cho’s leadership plays a pivotal role in steering the airline through these turbulent waters, focusing on implementing strategic partnerships to smooth out supply chain inefficiencies. By enhancing relationships with manufacturers and suppliers of aircraft components, Korean Air can better position itself to mitigate the impact of these supply chain disruptions.

Moreover, addressing these supply chain issues is more pressing than ever in light of the aviation industry’s recovery post-pandemic. Airlines are experiencing a surge in passenger demand, which amplifies the urgency to expand capacity rapidly. Korean Air’s proactive approach toward optimizing its supply chain management can help leverage opportunities in a recovering market, enabling quicker turnarounds for fleet expansion. Cho’s strategies, therefore, extend beyond mere problem-solving to encompass long-term planning for resilience in the airline’s operational framework.

The Trump Tariff Impact on Korean Air

Trump’s tariffs introduced complexities in the aviation supply chain, dramatically affecting how Korean Air procures essential aircraft components. Such tariffs can lead to increased costs and longer wait times for deliveries, challenges that Walter Cho has identified as significant threats to the airline’s operational efficiency. Recognizing the repercussions of these tariffs is vital for developing strategies that can mitigate financial strain and maintain pricing competitiveness in the market. Thus, adapting to these regulatory changes has become a key aspect of Korean Air’s operational planning.

In addressing the impact of tariffs, Korean Air is exploring alternative sourcing strategies and diversifying its supply chain to lessen dependency on affected regions. By seeking partnerships with suppliers in countries less impacted by these tariffs, the airline aims to streamline procurement processes while controlling costs. Moreover, advocating for policy changes that support the industry could create a more favorable trading environment. Ultimately, adapting to the tariff landscape is paramount for maintaining competitive advantage and ensuring stability in operational planning.

Addressing Airline Industry Challenges

The airline industry is fraught with challenges, particularly as it recovers from the pandemic’s repercussions. Beyond just supply chain shortages, airlines face the growing necessity for enhanced customer experiences, operational efficiency, and sustainability initiatives. Walter Cho understands that addressing these multifaceted challenges is critical for Korean Air’s survival and success in the coming years. With increasing competition, especially from low-cost carriers, there is no room for complacency when it comes to meeting industry standards.

Furthermore, developing agile operational strategies tailored to current circumstances can empower Korean Air to respond effectively to market demands. This includes investing in technological advancements to improve efficiency and customer engagement. By leveraging data analytics and automation in their supply chain operations, the airline can identify potential disruptions early and adapt swiftly. As the industry evolves, Korean Air must remain at the forefront of innovation to tackle the challenges that lie ahead.

Strategic Solutions for a Competitive Edge

To maintain a competitive edge in the aviation landscape, Korean Air must implement strategic solutions tailored to tackle its specific challenges. Under Walter Cho’s leadership, the focus is on integrating advanced technology into operations, which can streamline processes and enhance decision-making capabilities. By investing in digital tools that allow for real-time monitoring of supply chain variables, Korean Air can preemptively address shortages, enabling more resilient operations.

Additionally, fostering collaborative relationships with other industry players is essential for achieving synergy and resource-sharing benefits. Korean Air could explore partnerships not just with other airlines but also with tech companies that specialize in logistics or airport management. By building a collaborative network, the airline can enhance its operational robustness while ensuring it is well-equipped to adapt to the rapidly changing demands of the aviation market. Strategic alliances could prove instrumental in overcoming the inherent challenges facing the airline industry.

Future Outlook for Korean Air and Asiana Merger

The future outlook for Korean Air post-merger with Asiana presents both opportunities and challenges. If managed effectively, the merger could position the combined entity as a dominant player in the Asian airline market, streamlining operations while expanding routes and services. However, this ambitious vision must navigate through significant supply chain issues that could hinder immediate operations. Walter Cho recognizes that addressing these logistical difficulties is crucial not only for the merger’s success but also for long-term viability in an increasingly competitive environment.

Moreover, the focus on innovation will play a key role in determining how effectively the newly formed airline adapts to market changes. This includes re-evaluating fleet compositions to ensure they are equipped with fuel-efficient and advanced aircraft that align with sustainability goals. As the merged entity aims for operational excellence, continuous improvement in supply chain capabilities will be pivotal in securing a competitive advantage in the future landscape of aviation.

Innovations in Aviation Operations

In the fast-evolving aviation industry, innovation has become a critical factor for survival and growth. Korean Air’s commitment to embracing new technologies stands as a testament to its determination to address contemporary challenges. Under the guidance of Walter Cho, the airline is exploring innovations in operations, particularly concerning maintenance and customer service enhancements. Implementing predictive maintenance using advanced analytics can reduce aircraft downtime and ensure that fleet availability aligns with demand.

Furthermore, customer experience innovations are essential for attracting and retaining passengers. Korean Air can leverage technology not only to streamline booking and check-in processes but also to enhance in-flight experiences, utilizing features like personalized entertainment systems and tailored meal options. By focusing on these innovations, Korean Air will be better equipped to differentiate itself from competitors while addressing customers’ evolving expectations in today’s aviation landscape.

The Role of Leadership in Aviation Supply Chain Management

Leadership plays an indispensable role in shaping an airline’s response to supply chain challenges. Walter Cho’s vision for Korean Air emphasizes proactive engagement with suppliers and stakeholders to create a resilient supply chain framework. His approach involves not only identifying problems but also generating comprehensive strategies that can adapt to unforeseen disruptions. Strong leadership in supply chain management means fostering a culture of collaboration and transparency, ensuring everyone from executives to ground staff is aligned towards common operational goals.

Moreover, effective leadership contributes to building a flexible workforce capable of responding to the dynamic nature of the aviation industry. As market conditions fluctuate, the ability to adapt quickly and pivot operational strategies becomes paramount. By empowering employees with training and resources, Korean Air can establish a knowledgeable team responsive to the complexities of supply chain management. Ultimately, elevating leadership’s role ensures Korean Air is better prepared to face supply chain challenges head-on.

Frequently Asked Questions

What are the major Korean Air supply chain challenges due to the merger with Asiana Airlines?

The merger of Korean Air with Asiana Airlines has led to significant challenges in the supply chain, primarily related to integrating operations and resources. This includes difficulties in acquiring sufficient aircraft and engines, which are essential for expanding their fleet and enhancing operational efficiency.

How is Walter Cho addressing Korean Air supply chain shortages?

Walter Cho, CEO and Chairman of Korean Air, is actively seeking strategic solutions to tackle the ongoing supply chain shortages. His focus includes improving partnerships with suppliers and optimizing procurement processes to ensure the airline can acquire the necessary planes and engines amidst increasing aviation supply chain issues.

What impact do Trump’s tariffs have on Korean Air’s supply chain issues?

Trump’s tariffs have exacerbated Korean Air’s supply chain challenges by increasing costs for imported components, which affects the pricing and availability of necessary equipment. This situation complicates the airline’s strategy, particularly during the merger with Asiana Airlines, as they strive to maintain competitive pricing and service quality.

What are the key airline industry challenges that affect Korean Air’s supply chain?

Korean Air faces several airline industry challenges, including fluctuating fuel prices, regulatory compliance, and intense competition. These factors, combined with the ongoing supply chain issues related to the Asiana merger and tariffs, create a complex environment for operations and growth.

How does the merger with Asiana Airlines influence Korean Air’s supply chain strategy?

The merger with Asiana Airlines significantly influences Korean Air’s supply chain strategy by necessitating a comprehensive review of existing logistics and resource management practices. This integration aims to streamline operations and mitigate the supply shortages that have hampered growth and efficiency.

| Key Points |

|---|

| Korean Air is facing supply chain shortages affecting operations. |

| CEO Walter Cho addresses challenges from Trump’s tariffs. |

| Merger with Asiana Airlines presents both opportunities and challenges. |

| Significant implications for the acquisition of planes and engines. |

| Strategic solutions are necessary for competitive advantage in the market. |

Summary

Korean Air Supply Chain Challenges are at the forefront of the airline’s operations. The company is grappling with critical shortages that impede its ability to acquire essential planes and engines. The CEO, Walter Cho, highlights the pressing need for strategic solutions to navigate these challenges, particularly in light of the implications from Trump’s tariffs and the ongoing merger with Asiana Airlines. It is imperative for Korean Air to address these supply chain issues to sustain its competitiveness and adapt to the evolving dynamics of the aviation industry.